Welcome

Ramsons Engineering Co.

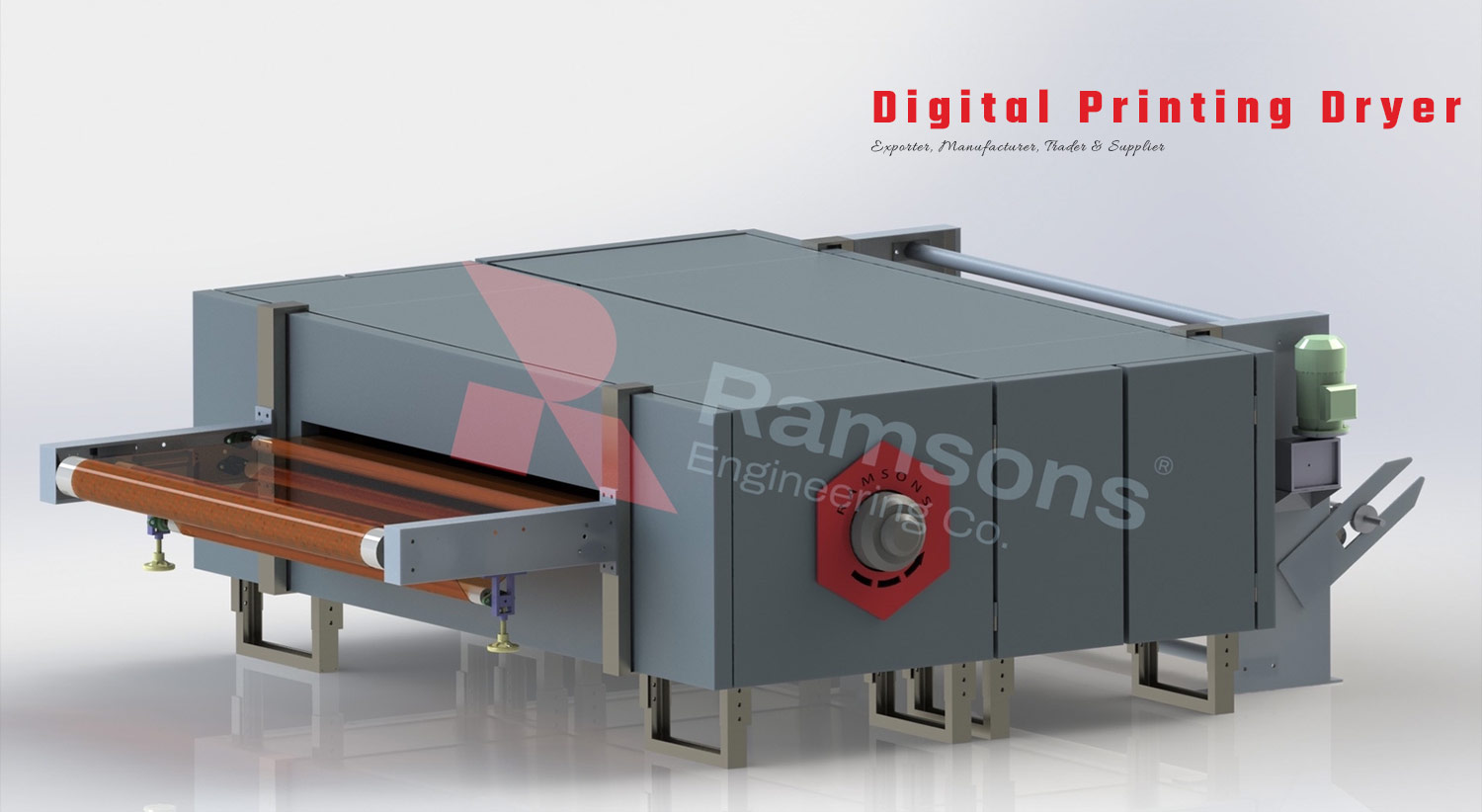

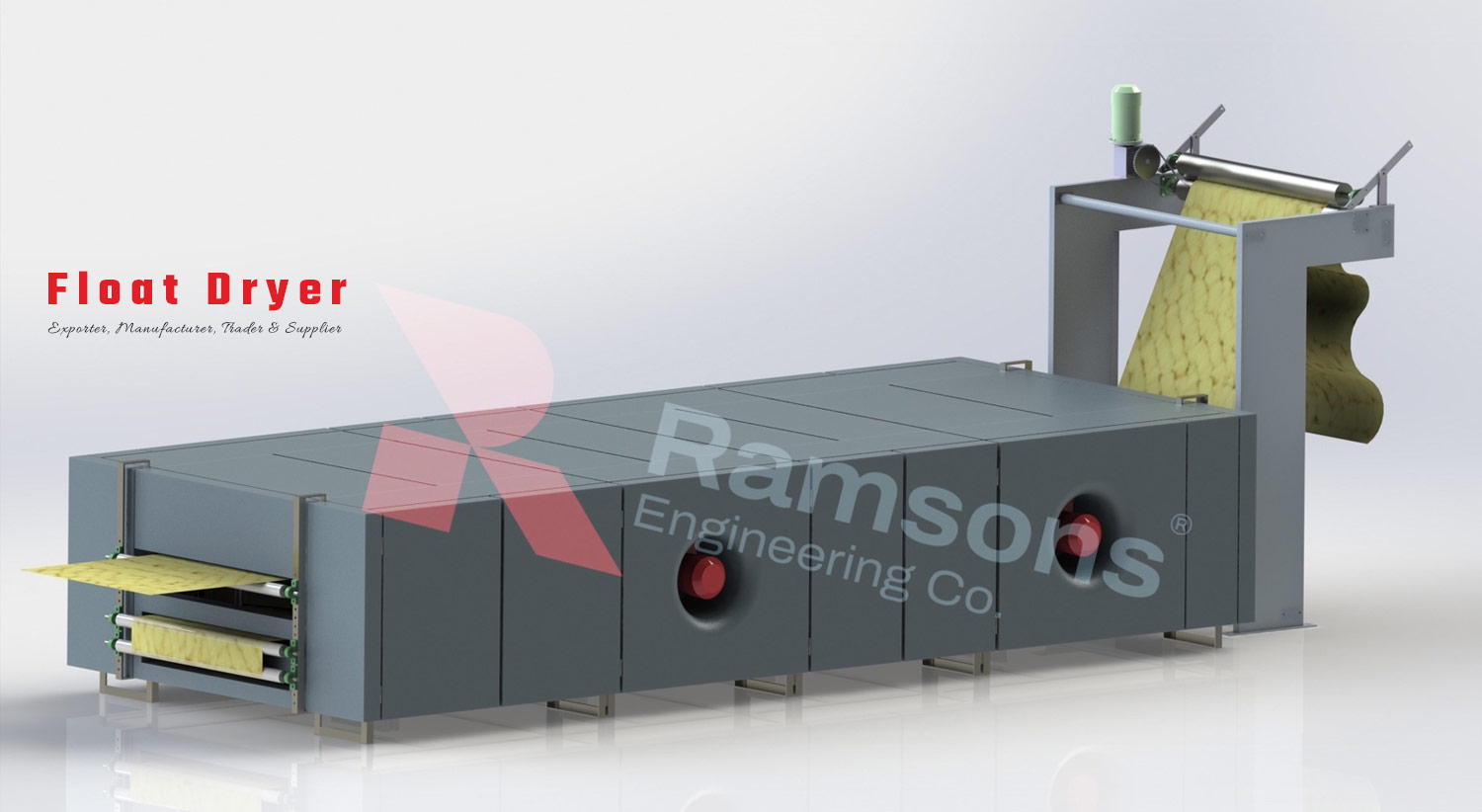

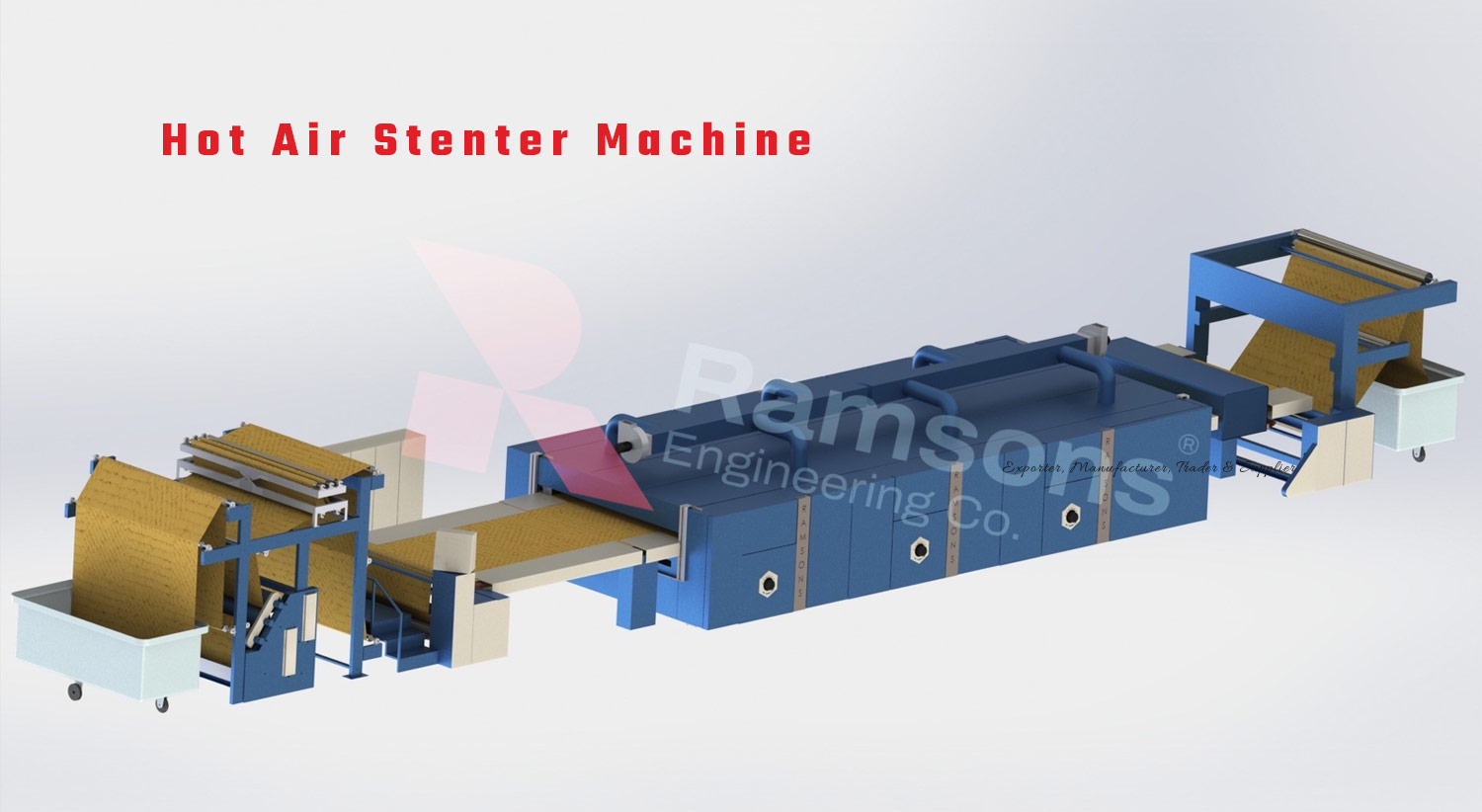

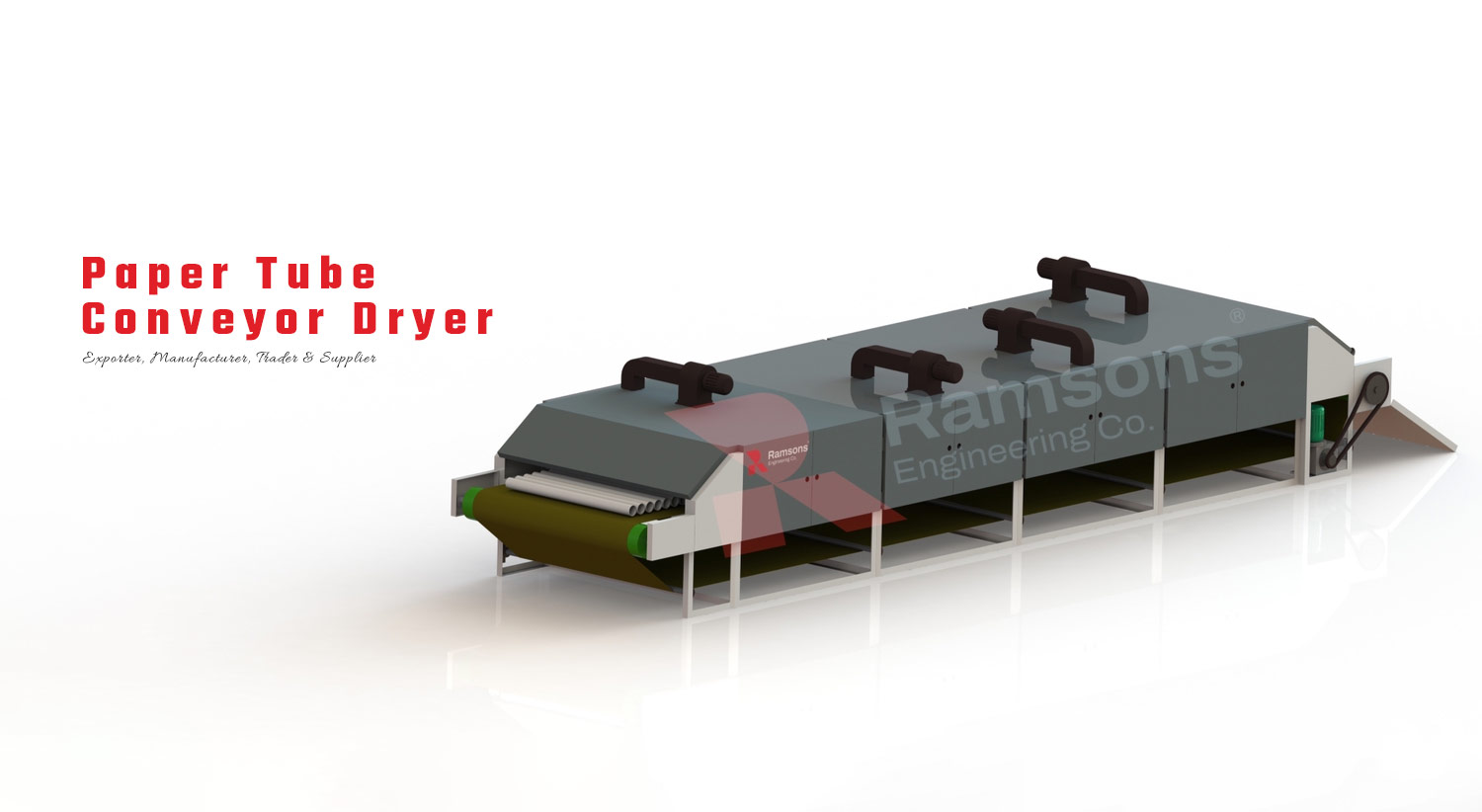

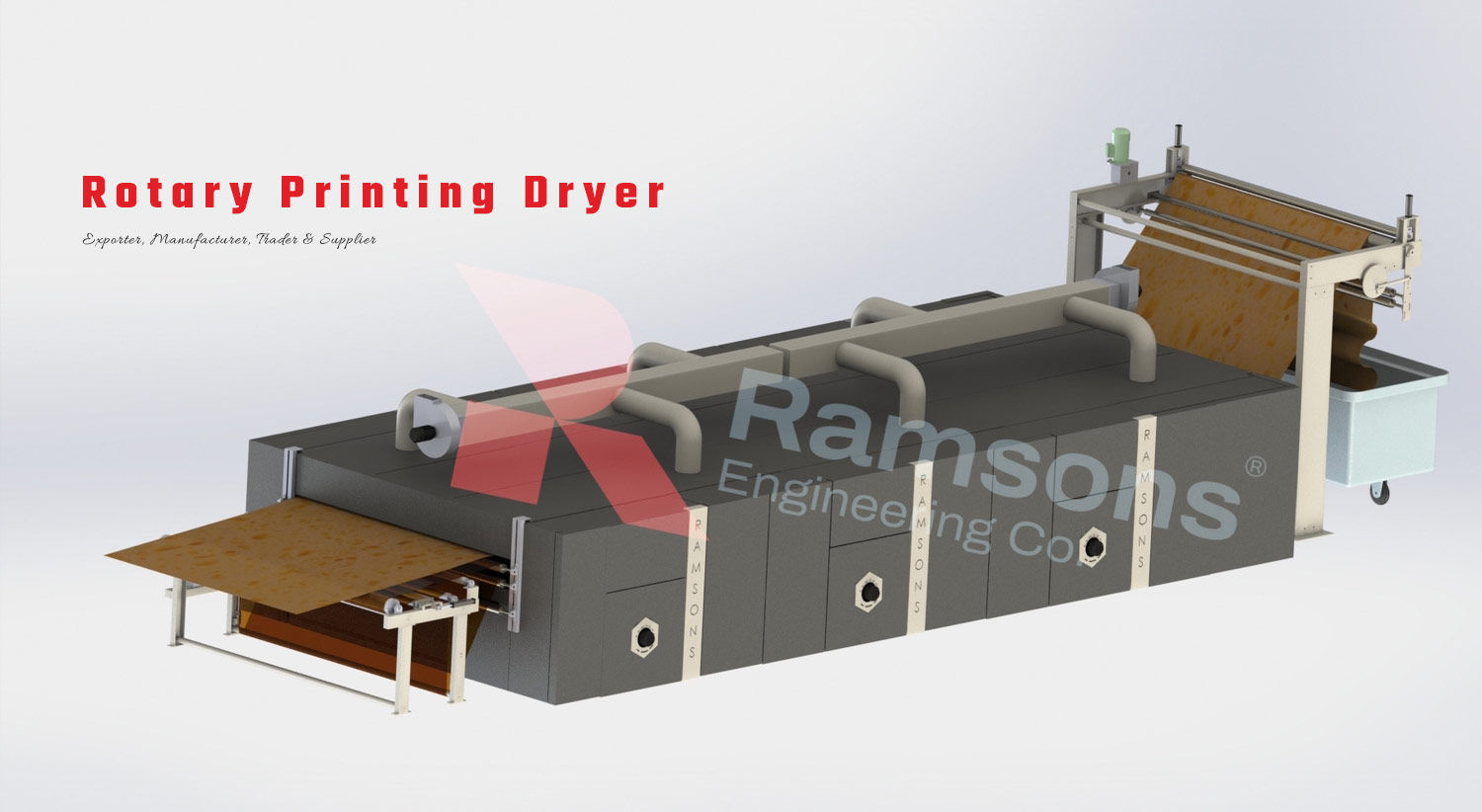

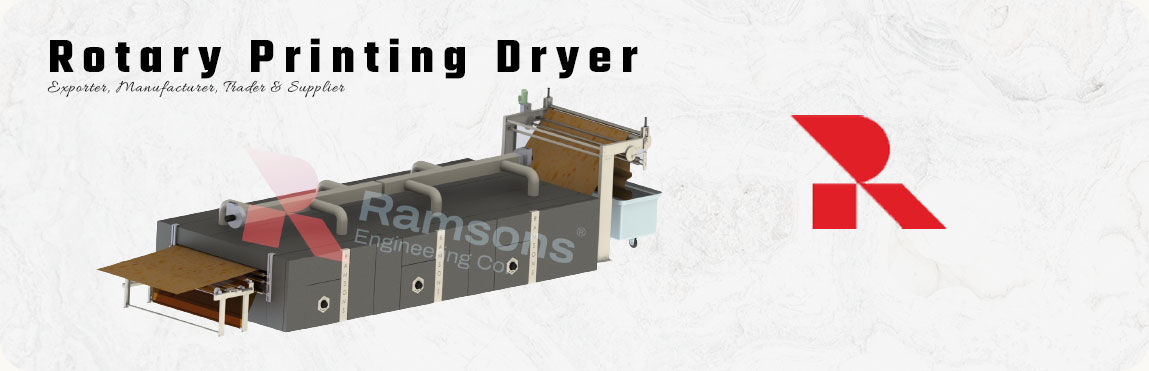

Offering a Wide Range of Products such as Printing Drying Machine, Textile Printing Dryer, Shade Dyeing m/c (Padding m/c), Paper Tube Dryer, Industrial Ovens and Yarn Dryer & Tray Dryer with Features of Durability, Performance and Long Productive Life.

With great pride and honor we introduce ourselves as Ramsons Engineering Co., one of the leading Manufacturer, Exporters, Suppliers and Traders of Printing Dryer, Printing Drying Machine, Textile Printing Dryer, Textile Dryer, Industrial Oven, Powder Coating Ovens, Paper Tube Dryer and many more. Our products are engineered in accordance to the technical specifications of international standards. Moreover, we have adopted rigorous procedures of in-house research and quality checking, which not only helps in keeping the products updated but also assist us in producing energy efficient products. As our products are widely used in the area of Dyeing and Printing Mill, Textile Industry, Paper Industry and Food Industry, they always remain in huge demand.

Most Popular Products

Exporter, Manufacturer, Trader & Supplier for products such as Textile Printing Dryer, Fabric Printing Drying Machine, Screen Dryer, Tray Dryer, Powder Coating Oven.

Why Choose Us

Quality Analysis

Rich experience of more than a decade and thorough understanding of the market has backed us to represent every job

Product Range

Our products are made of high grade raw materials which makes them durable and perfect. Moreover, we put best of effort

Infrastructure

We are backed by a state-of-the-art infrastructural setup. Our fully equipped infrastructure assist us to undertake

Call Me Free

Call Me Free